Where it all started : Matt Venn

I have a 1990,4×4, Sapphire Cosworth and, a little while ago I had my gearbox re-built. The builder dropped the casings back to me to paint along with the transmission coupling (rubber doughnut), saying I needed to get hold of a replacement. At that time I thought it wouldn’t be a problem. Little did I know that getting hold of a second-hand item would be almost impossible – let alone a new item. Manufacturing of these items ceased 20 years ago, with the last of the stock being sold over 10 years ago.

I made various posts and made lots of enquiries to various people/suppliers but to no avail.

It transpires that there are two types of doughnut. 1989-1991 used the old style – a chunky section with and internal, spherical bearing and seal. From 1992 onwards (which includes the Escort Cosworth), Ford installed a smaller item without the bearing. They changed the three-pronged yolk on the rear of the gearbox and the front section of the prop-shaft which now had the spherical bearing attached to it.

Different people offered alternative advice on how to use the new style doughnut with making modifications to the drive train. These included; cutting the spigot off of the rear of the gearbox, sourcing and fitting a later front half of the prop-shaft, etc, etc. Whilst some of these suggestions would work in principle, I didn’t really fancy chopping off sections of the gearbox, then trying to source a later, front section of the prop which would be subject to the usual “RS-Tax”.

I was getting concerned as there was no way I could put the old doughnut back on the car as it was likely to fail at any time. At the same time – I wanted to be able to drive my pride and joy.

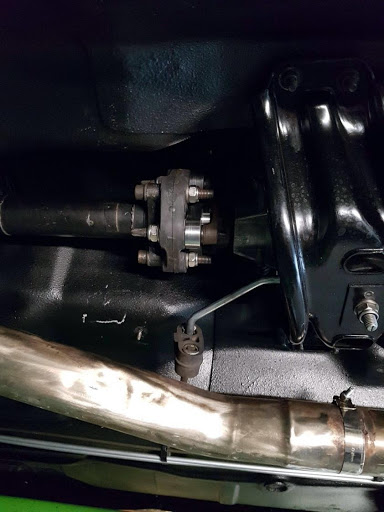

Seeing my frustration, Peter Johnson contacted me to discuss the possibility of designing and manufacturing an adaptor that’d allow the new style doughnut to be installed as a direct replacement part without the need of modification or replacement of existing drivetrain.

Over the last few Months, Pete and I have mocked-up, designed, tried and tested various adaptors with the new style doughnut. The last prototype has been a huge success and has performed faultlessly on Pete’s 4×4 Cosworth. It has around 400bhp and he drives it hard. The car has also been on the rolling road, again, performing without fuss. If anything, the drive train feels more solid that usual!

In essence, this adaptor replicates the original doughnut which includes the spherical bearing. We did wonder if we could delete the bearing, but, upon having a bearing-less prototype manufactured, during testing, we encountered vibration from 30mph. This very expensive prototype is now a very posh paper-weight! But, if you don’t try these things, you won’t know. Besides, we are more than aware that, whoever buys these things will be installing them into their pride and joy – Just like Pete and I. We’re trying to keep these fine machines on the road – not break them!